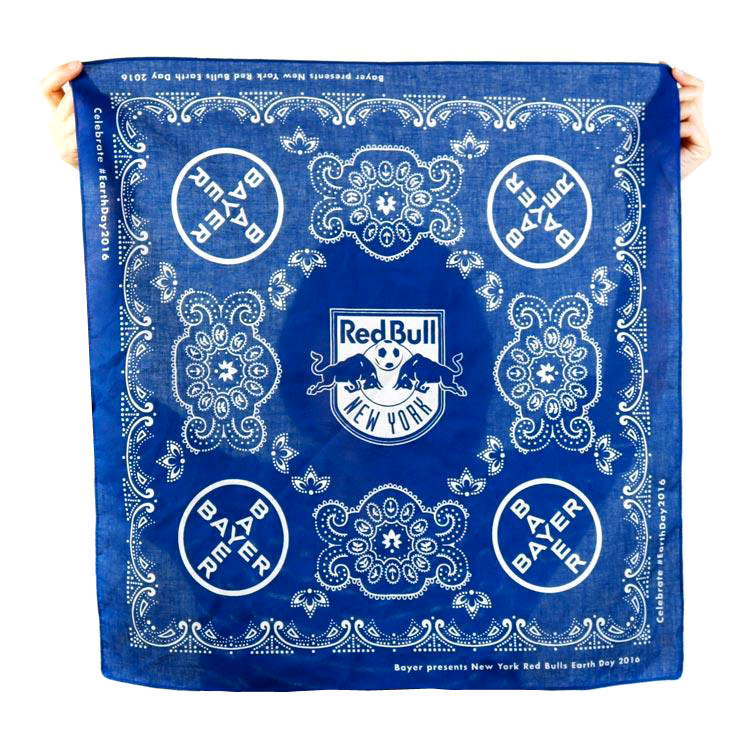

MASS PRODUCTION ORDER MINIMUM QUANTITY: 50PCS

Custom Cases

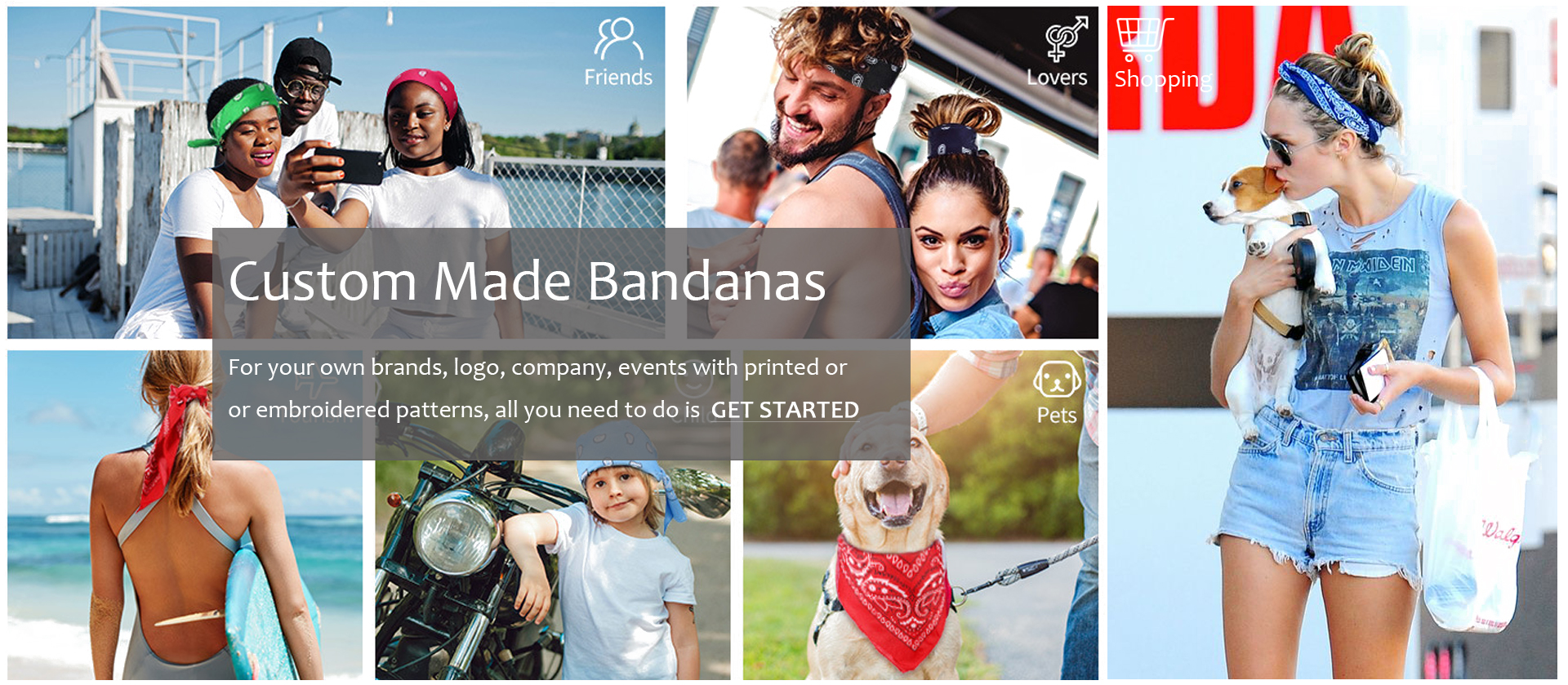

Custom Bandana Frequently Asked Questions

What's the turnaround time ?

Samples can be ready in 5-7 days, bulk order can be ready in 10-20 days according to the quantity.

What's the minimum quantity for custom bandanas ?

Normally the minimum quantity for custom bandanas is 30pcs each design, can be negotiated.

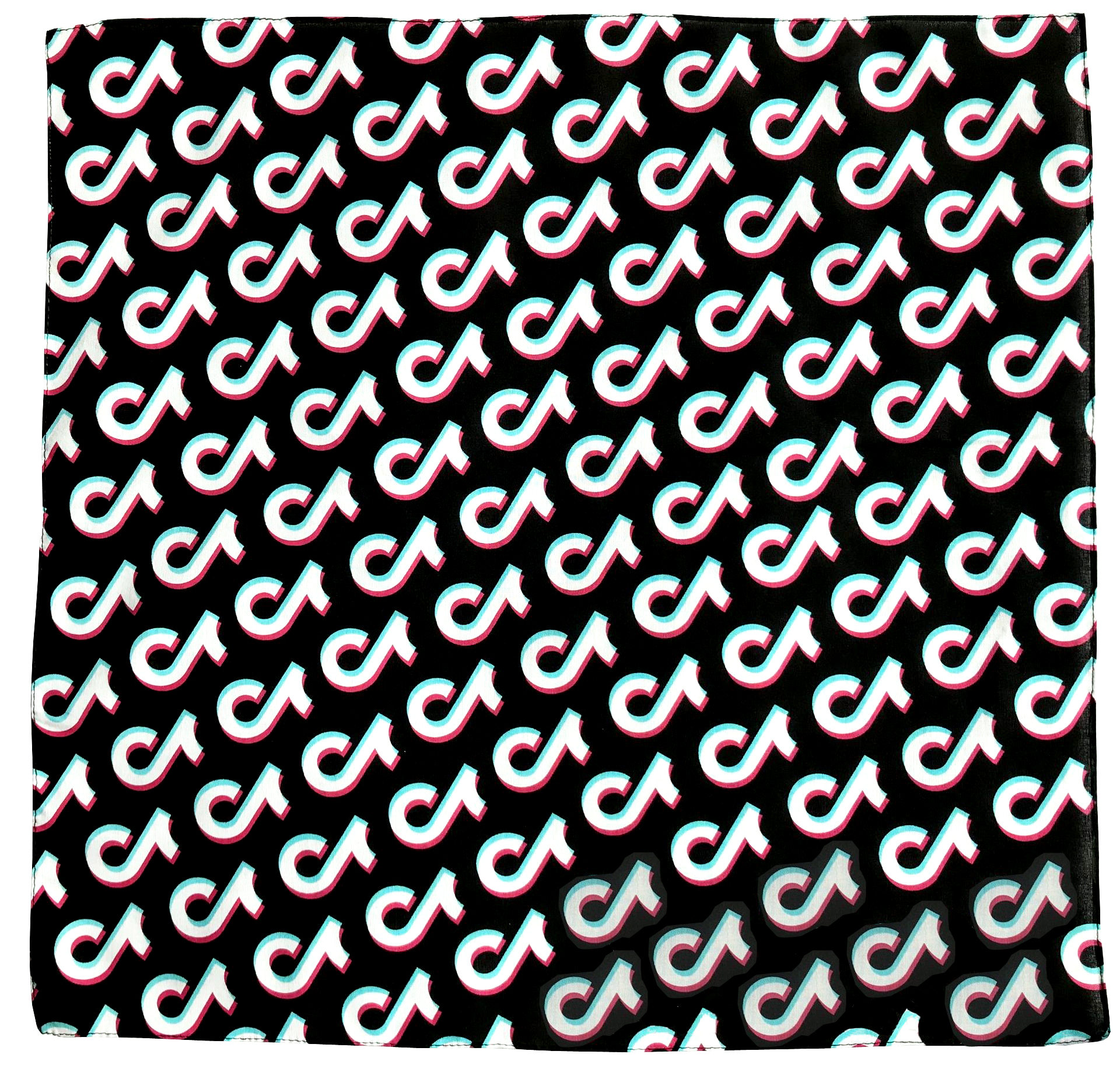

What are the available bandana colors ?

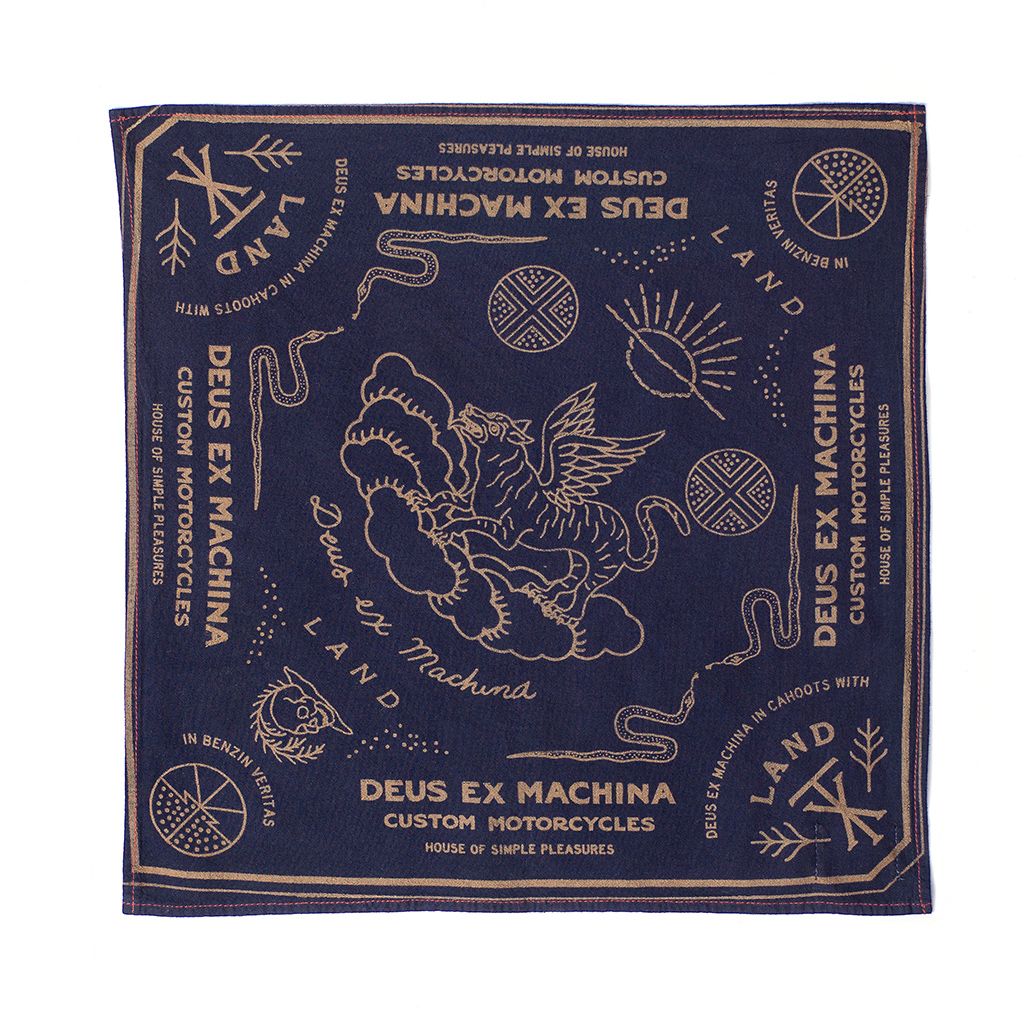

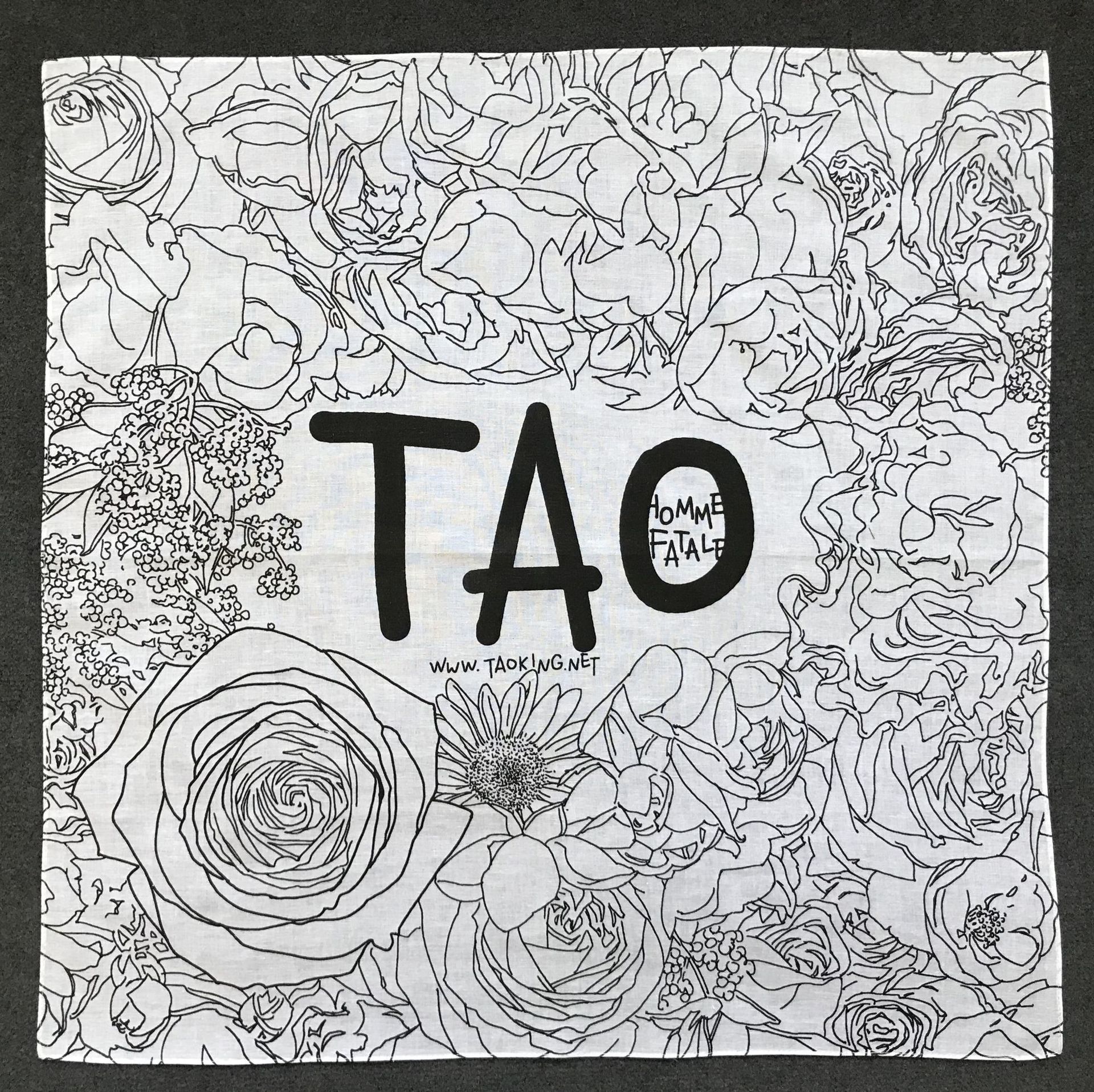

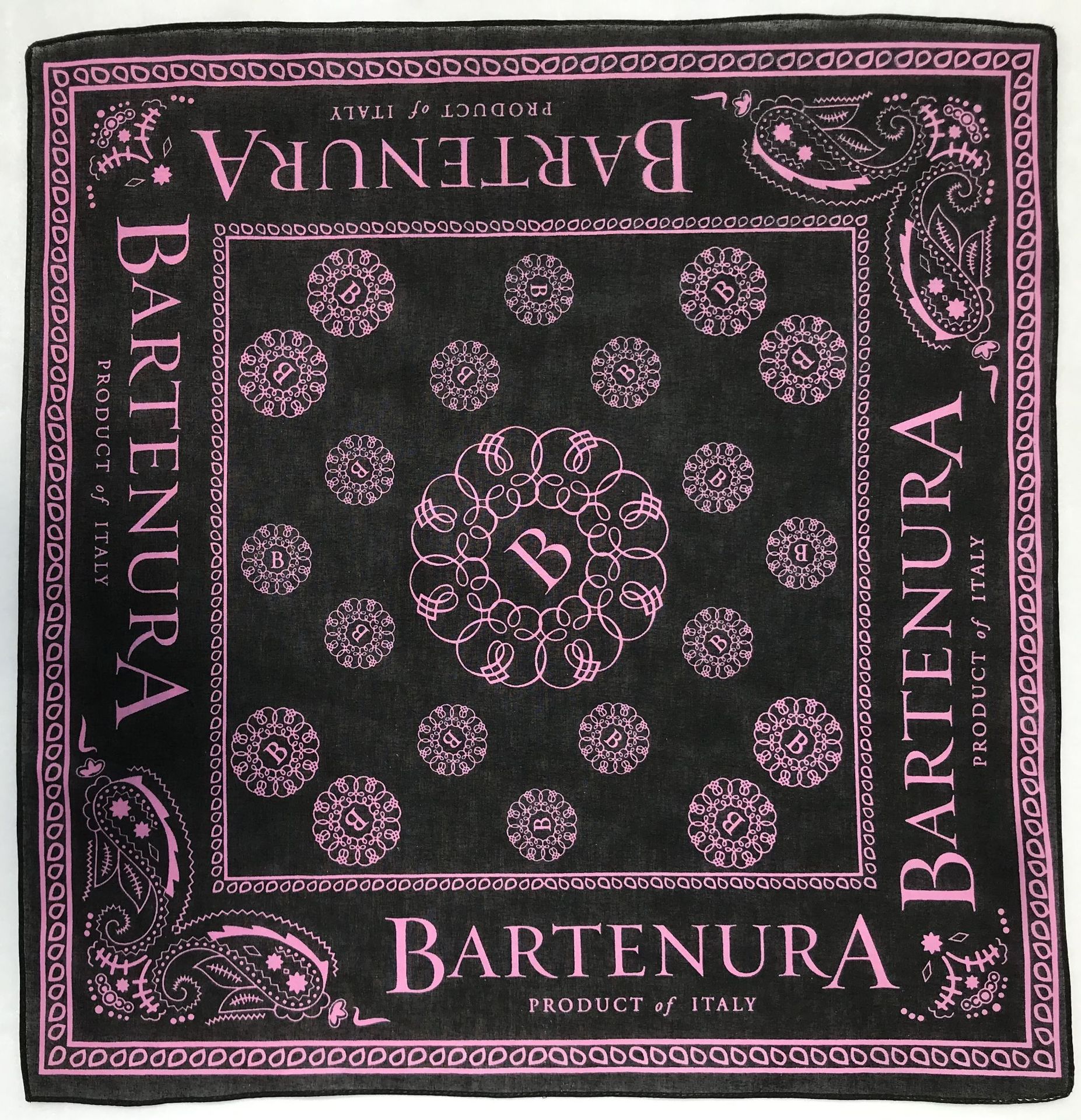

There is no colors limit for bandana, any color and any designs can be printed.

Where are the bandanas made ?

All bandanas will be made in China and shipped from China by Express like DHL, FedEx, 5-7 days to most countries around world.

Do you offer samples ?

Yes, free fabric swatches are available to provide, samples with your own designs will be charged$20-$30 according to the sizes and requirement.

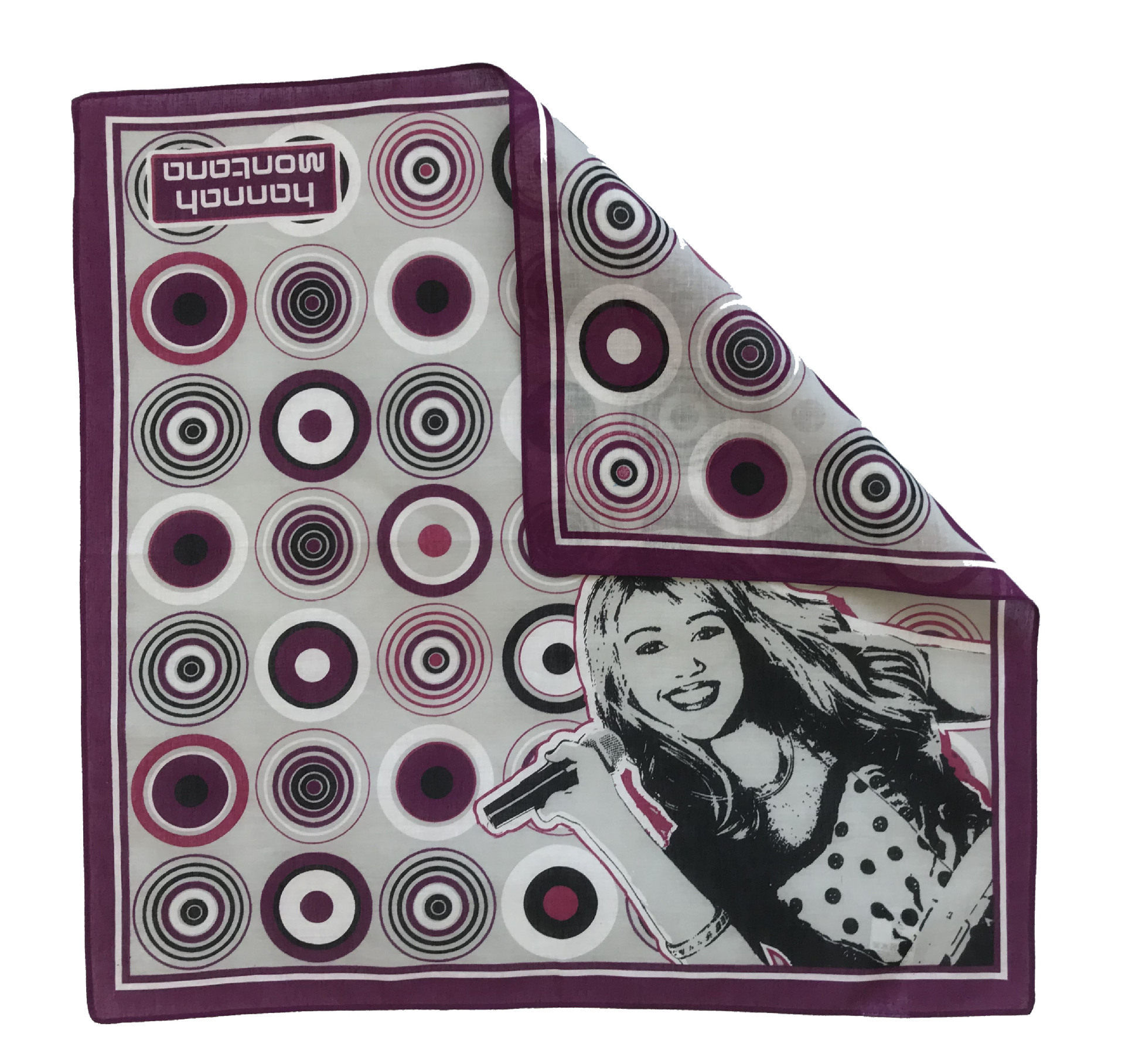

What file format is required for custom bandana ?

It can be jpg, pdf, ai, tif or psd files with no less than 200 dpi, the higher the better.

How do I upload the designs ?

For designs less than 20mb can be directly sent to email address [email protected], or through wetransfer.com to above email address if it is too large.

100 Satisfaction Guarantee ?

If you are in any way dissatisfied with the quality or service, we will arrange a reprint or issue a prompt refund. Your satisfaction is our top priority.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian