The development history of artifical silk ?

Artifical silk fabric manufacturing technology

Artifical silk is polyester fiber filament processed by a special craft and finishing, which makes the fiber finer and softer, so that it has a similar appearance, luster, feel and other effects of real silk.

Artifical silk has several major categories:

Chiffon (30D, 50D, 75D, 100D)

Crinkle Chiffon or Yoryu Chiffon (30D, 5D, 75D, 100D)

Satin Chiffon (30D,50D,75D) divided into elastic, composite.

Satin (50D*50D, 50D*75D, 75D*100D, 75D*75D, 75D*150D), divided into light, matte, elastic.

Twill (50D*50D, 50D*75D, 75D*100D, 75D*75D), divided into light, matte

The development history of artifical silk

Beginning in the 1960s, with the rapid development of synthetic fibers, the research and development of artifical silk came into being. Throughout the development of polyester artifical silk, it has experienced the following five important development stages:

The first stage (1962~1968)

Committed to the appearance of artifical silk. The products are treated with special-shaped cross-section yarn, ordinary polyester yarn, strong twist, false twist and alkali reduction processing technology, which makes product has silk luster, smooth feeling and wrinkle resistance.

The second stage (1969~1973)

Committed to the pursuit of silk style. The development of dyeable cationic polyester is the main symbol of the second generation. It makes artifical silk products closer to real silk in fiber structure and style, and added antistatic and antifouling functions.

The third stage (1973~1978)

Committed to a deeper level of artifical of the appearance and beauty of silk. It has developed high multifilament, super multifilament and interlaced yarn products which based on physical modification. Fine denier filament and fiber blending technology are the main symbol of the third generation. At the same time, with the developing of polygonal and shaped cross-sectional yarns, and improving of color depth and vividness in dyeing and finishing technology, the fabric is more comfortable, soft, fluffy like real silk and not easy to pilling.

The fourth stage (1979~1984)

Committed to approaching the essence of silk. During this period, polyester filament ultra-fine denier, special-shaped, and fiber blending technologies were fully developed, and a variety of technologies were applied to make polyester filaments have silk-like silkiness and luster, as well as good hygroscopicity and antifouling properties.

The fifth stage (since 1985)

Committed to the development of "artifical silk that better than silk". In addition to maintaining the fine silk-like style, the new generation of polyester artifical silk also focuses on "integration", which is not only integrates the culmination of silk style, but also has its own characteristics.

After more than 50 years of development, artifical silk products have changed from simply imitating the silk luster and organizational structure, to imitating the comfort of silk, and some have even reached the status of "superiority". Based on the characteristics of strong plasticity of chemical fibers, more new functions that meet consumer needs have been added, such as antibacterial, sunscreen, ceramic health, etc.

Artifical silk fabric manufacturing technology

1 Ordinary polyester filament technology

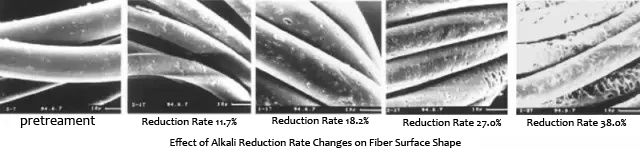

Mainly in the weaving stage, by 15%~35% alkali reduction processing to improve the fiber hand feeling, to make it closer to silk. Polyester fiber is hydrolyzed under the action of hot strong alkali, so that the surface of the fiber is eroded, uneven and cracked, the structure is loose, the fiber becomes thinner, the weight is reduced, the interlacing resistance and the rigidity of the fabric is reduced to obtain a soft feel, soft luster and good drape properties like natural silk.

2 Change the shape of the fiber cross section

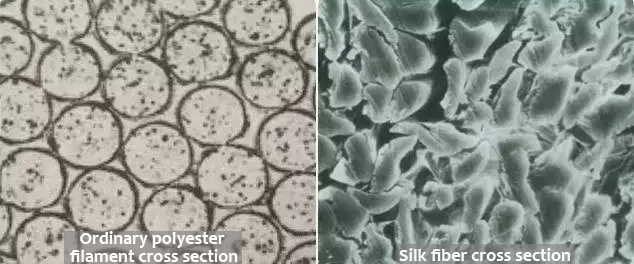

The cross-section of ordinary polyester filament is round, and the fabric formed is relatively smooth, waxy, and easy to reflect all light. The fabric woven by it is quite different from silk fabric.

The cross section of silk is similar to a triangle, so that it can play the role of a prism in contact with light, that is, it transmits a part of the light and reflects a part of the light, has low surface reflection light, such a cross section. Make silk fabrics show its unique, soft luster.

Nowadays, the fiber section has developed from triangle to polygon, Y-shaped, H-shaped and star-shaped, etc., and hollow section has also come out. These special-shaped yarns can eliminate part of the reflection, make the luster soft and improve the hand feeling; at the same time, it also improve the moisture permeability, air permeability and stain resistance of the fabric. These properties enable imitation silk products not only to be close to real silk products in appearance, but also in terms of luster and bulkiness.

3 Fine denier filament technology

The excellent drape, pearly luster and soft feel of silk fabrics are largely due to their finer denier. Therefore, in the research of artifical silk, fine denier is an important direction.

The use of fine-fiber filament raw materials increases the layered structure of the silk in the product, thereby enhancing the ability of the fiber to reflect light inside, making the fiber fabric show a more delicate luster, and further imitating the luster characteristics of silk products.

In addition, benefits of the high degree of fine fibrillation of the raw material, the fineness of the single fiber in this kind of artifical silk product is slimmer, and the hand feeling of the fabric can be further improved. This technology has also been widely used in practical production.

For example

Georgette crepe is made of fine denier filament and strong twisting technology, combined with alkali reduction process, and finally made it close to silk crepe. Compared with silk products, it showed better wearing performance which greatly improve the application of such products in the field of clothing.

4 Artifical silk with strong twist, false twist, uneven thickness and surface modification technology

Through strong twisting, false twisting and other processing technologies, the dispersibility, smoothness and roughness of polyester monofilament can be improved, and the bulking rate, crimp rate and shrinkage rate of warp and weft can be consciously controlled, so as to obtain fluffy, soft, elastic and crepe effects. Through the uneven thickness drafting, the phenomenon of uneven thickness in the longitudinal direction of the monofilament makes the appearance and style closer to the natural silk, and the distribution effect of the same thickness of the fabric is obtained. In addition, the surface modification can better highlight the microstructural characteristics of silk, on the one hand to obtain natural unevenness, and on the other hand, the tiny cracks after surface treatment make the fiber surface better luster and silky feeling.

5 Microporous composite fiber

Since polyester is a hydrophobic fiber, in the manufacturing process of artifical silk, the fabric has disadvantages such as poor air permeability, no sweat absorption and poor wearing comfort. In order to solve this problem, people have developed a microporous composite fiber, which adopts the physical method of blending hollow and the chemical method of alkali reduction treatment to obtain the microporous structure, so that there are voids inside the fiber to improve the water absorption and hygroscopicity. Therefore, when producing highly absorbent and hygroscopic artifical silk fabrics, many product developers will give priority to using microporous composite fiber to achieve this function.

After decades of development, the products using polyester as the raw material have reached the level of real silk in both appearance and feel. Artifical silk products have the advantages of both natural and synthetic fibers, with silk style, light and elegant, soft and smooth, gentle luster, good drape, comfortable to wear, wear-resistant, non-iron, anti-wrinkle, washable.

In the future, the raw materials of artifical silk will develop in a diversified direction, and at the same time, it will be more closely matched with the subsequent dyeing and finishing process to achieve a more excellent effect of artifical silk.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian

Leave A Comment